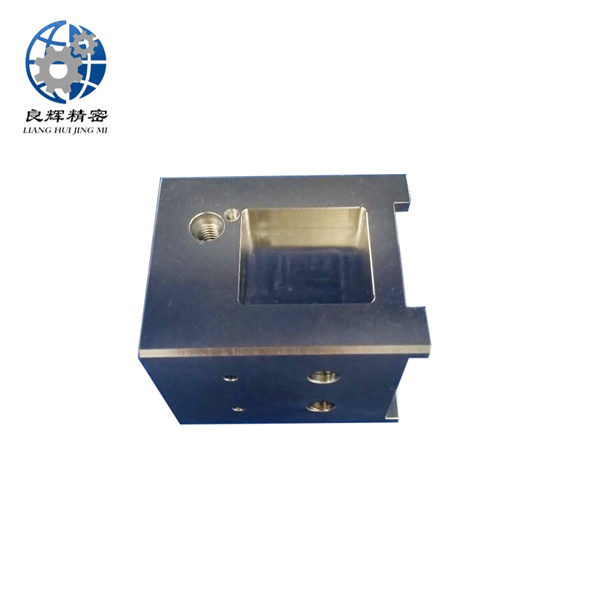

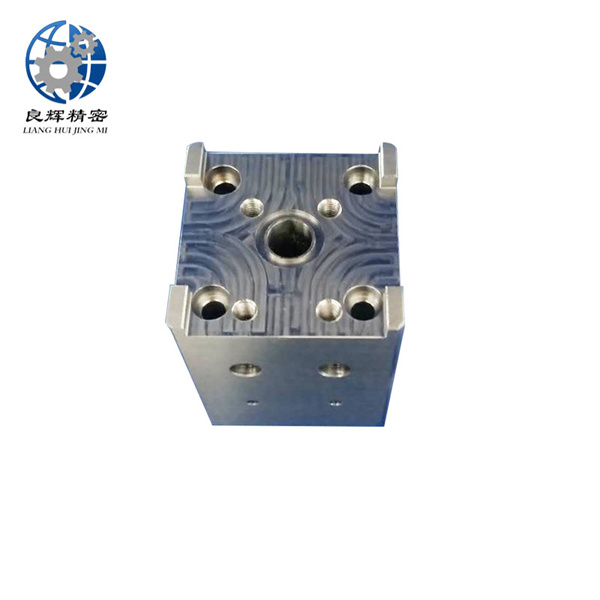

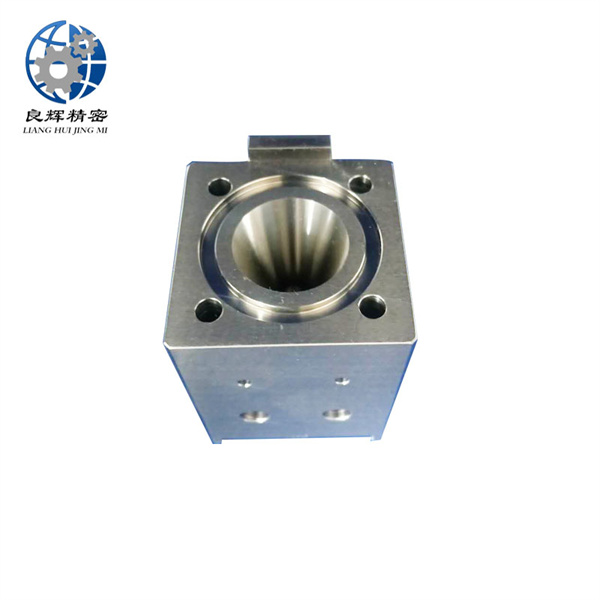

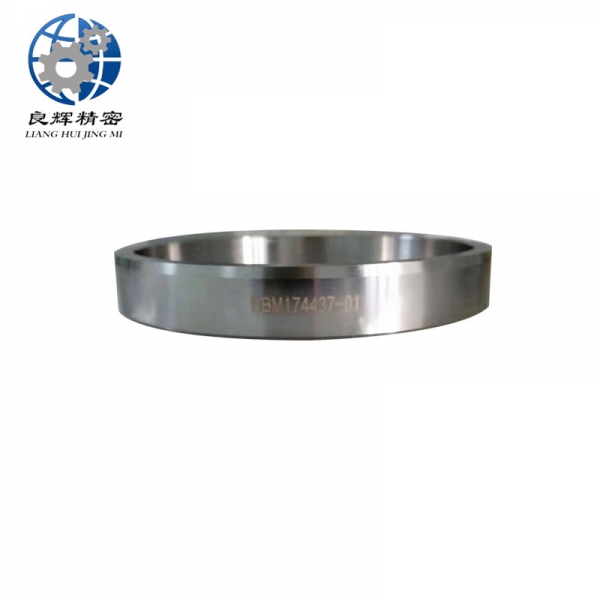

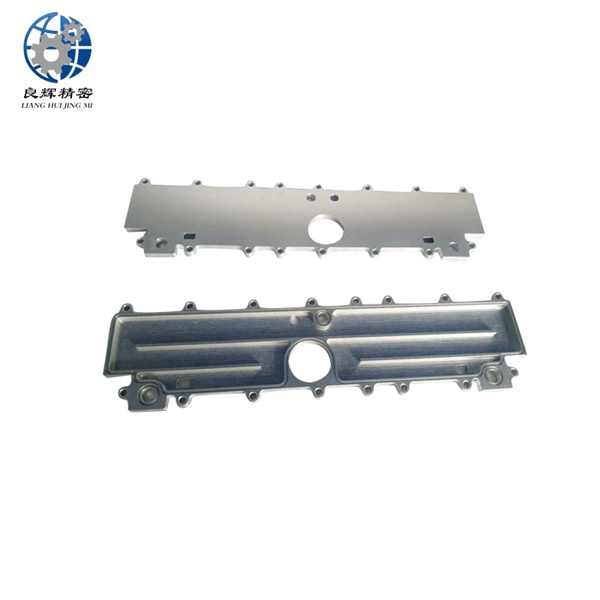

白鋼閥塊用于電液伺服控制系統(tǒng),在TRT裝置中,屬于八大系統(tǒng)之一的分系統(tǒng)。

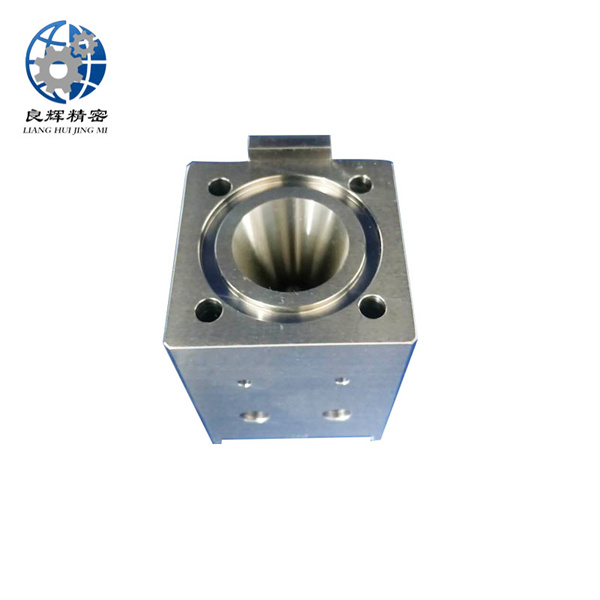

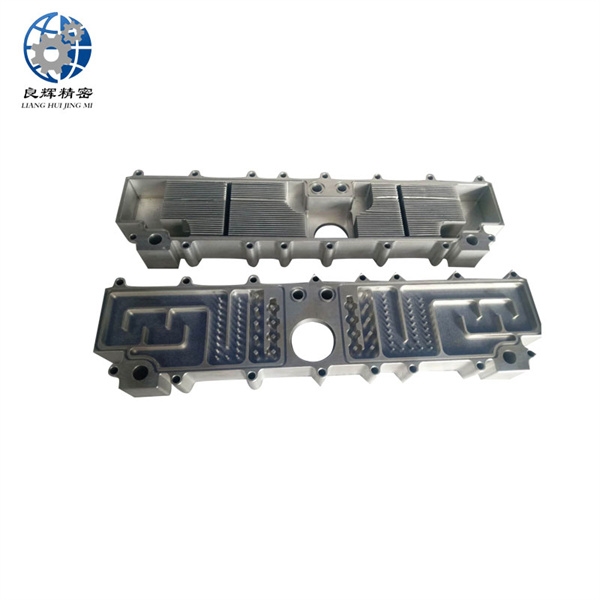

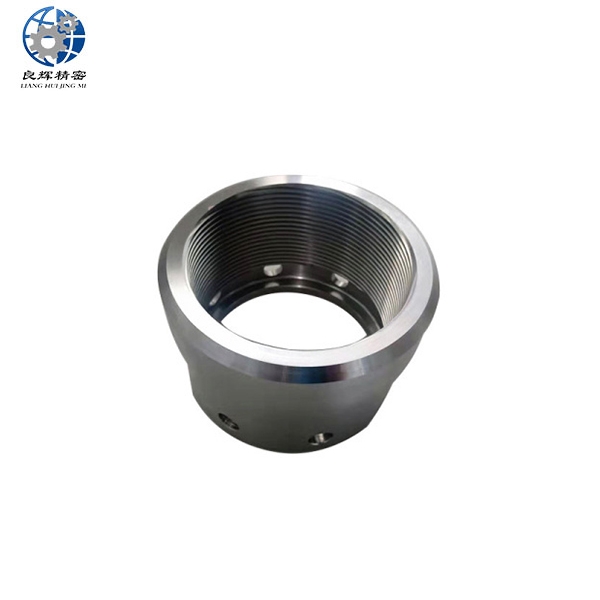

閥塊的失效主要表現(xiàn)有孔和桿之間配合間隙過(guò)大、動(dòng)態(tài)密封磨損、控制臺(tái)肩磨損、閱的氣蝕等。大連精密零部件加工廠家歸納出形式有以下三點(diǎn):

(1)性能退化:約占失效的15%;

(2)性能下降:約占失效的70%,分為腐蝕和機(jī)械磨損,機(jī)械磨損又可細(xì)分為磨損、老化、粘合損壞;

(3)意外事故:約占失效的15%。

出現(xiàn)閥塊失效最主要的兩大原因是:

(1)油液的清潔度不夠;

(2)系統(tǒng)進(jìn)入空氣。

The white steel valve block is used in the electro-hydraulic servo control system and is a subsystem of one of the eight major systems in the TRT device.

The main manifestations of valve block failure include excessive clearance between the hole and the rod, dynamic seal wear, console shoulder wear, and cavitation. Dalian precision parts processing manufacturers have summarized the following three forms:

(1) Performance degradation: accounting for approximately 15% of failures;

(2) Performance degradation: accounting for about 70% of failures, it is divided into corrosion and mechanical wear, and mechanical wear can be further divided into wear, aging, and adhesive damage;

(3) Accidents: accounting for approximately 15% of failures.

The two main reasons for valve block failure are:

(1) The cleanliness of the oil is insufficient;

(2) The system enters the air.