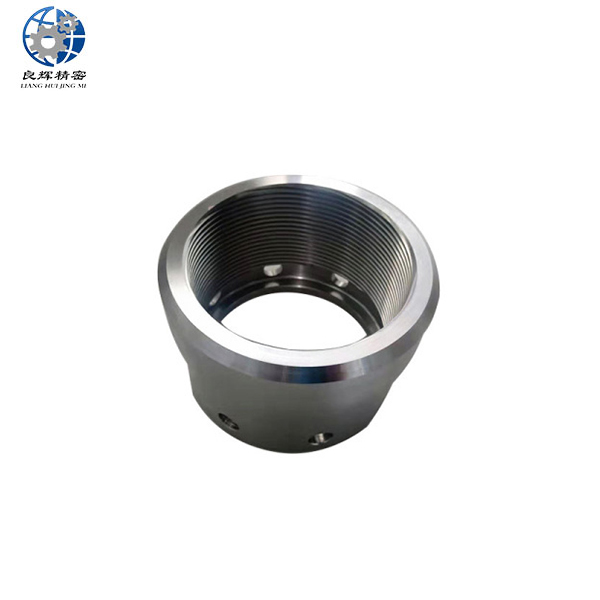

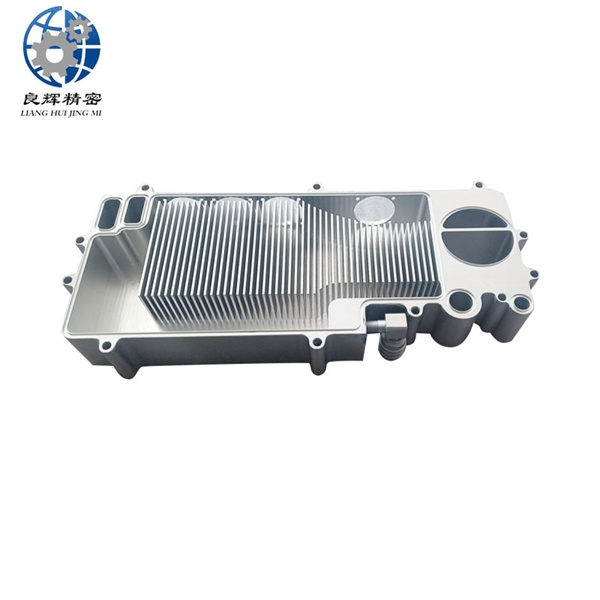

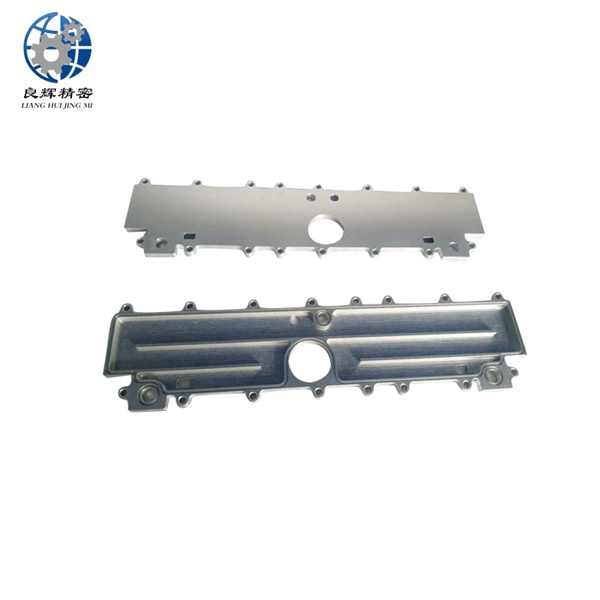

大連數(shù)控加工是在數(shù)控機床上進行零件加工的一種工藝方法,數(shù)控機床加工與傳統(tǒng)機床加工的工藝規(guī)程從總體上說是一致的,但也發(fā)生了明顯的變化。用數(shù)字信息控制零件和刀具位移的機械加工方法,它是解決零件品種多變、批量小、形狀復雜、精度高等問題和實現(xiàn)高效化和自動化加工的有效途徑。

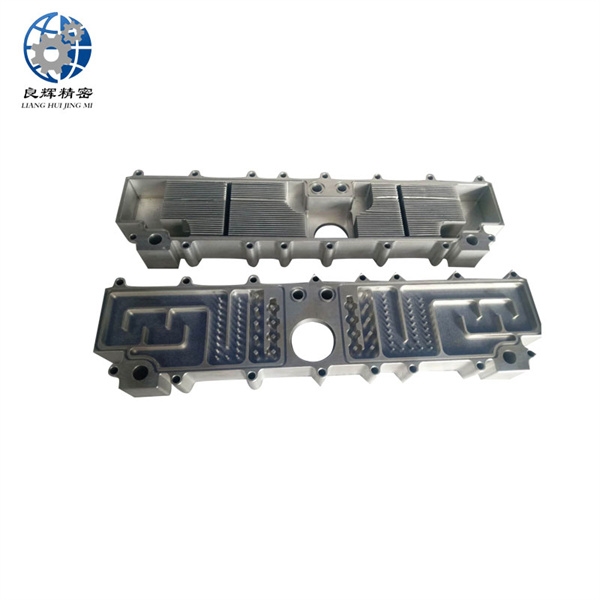

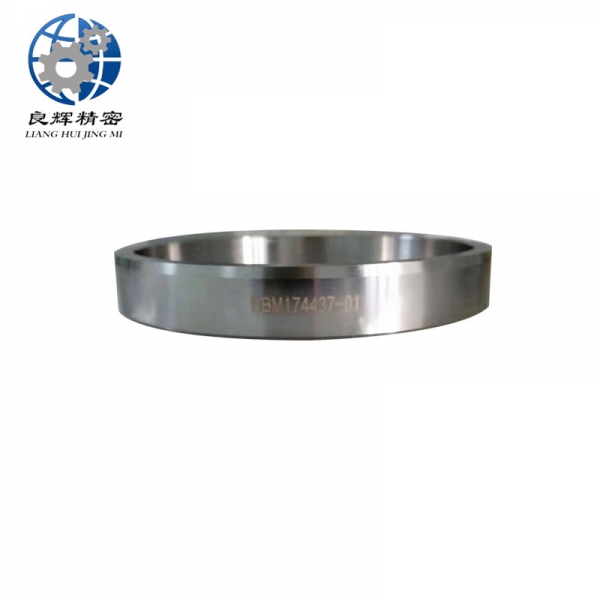

數(shù)控機床一開始就選定具有復雜型面的飛機零件作為加工對象,解決普通的加工方法難以解決的關鍵。數(shù)控加工的最大特點是用穿孔帶(或磁帶)控制機床進行自動加工。由于飛機、火箭和發(fā)動機零件各有不同的特點:飛機和火箭的零、構件尺寸大、型面復雜;發(fā)動機零、構件尺寸小、精度高。

Dalian CNC machining is a process method for machining parts on CNC machine tools. The process specifications for CNC machine tool machining and traditional machine tool machining are generally consistent, but there have also been significant changes. The mechanical processing method that uses digital information to control the displacement of parts and cutting tools is an effective way to solve problems such as variable part varieties, small batch sizes, complex shapes, high precision, and achieve efficient and automated processing.

From the beginning, CNC machine tools select aircraft parts with complex profiles as the machining objects, solving the key problems that ordinary machining methods are difficult to solve. The biggest feature of CNC machining is the use of perforated tape (or magnetic tape) to control the machine tool for automatic machining. Due to the different characteristics of aircraft, rockets, and engine components: large component sizes and complex profiles of aircraft and rockets; Engine components have small dimensions and high precision.