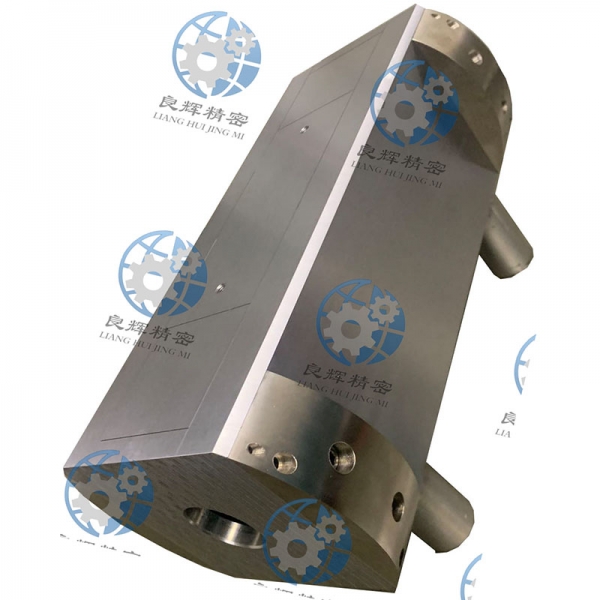

機封零件,俗稱“機械密封件”,是機械設備中的一個重要部件,用于防止液體或氣體從機器的旋轉軸芯或活塞軸向逸出,并且防止外部物質侵入。機封零件在各種工業領域中廣泛應用,包括化工、石油、電力、造紙、制藥等行業。大連精密零部件加工

機封零件的主要作用是防止介質泄漏和保護設備的正常運轉,其性能直接關系到設備的工作效率和壽命。目前,隨著工業技術的不斷發展,機封零件的種類和規格也越來越多樣化,以適應不同工況下的使用要求。

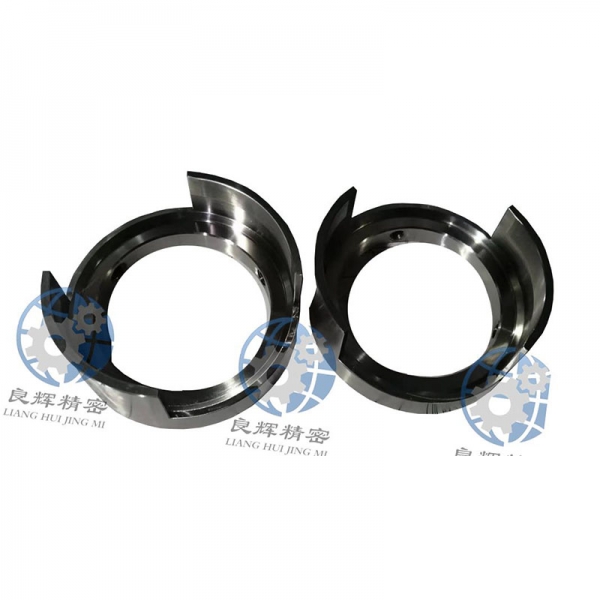

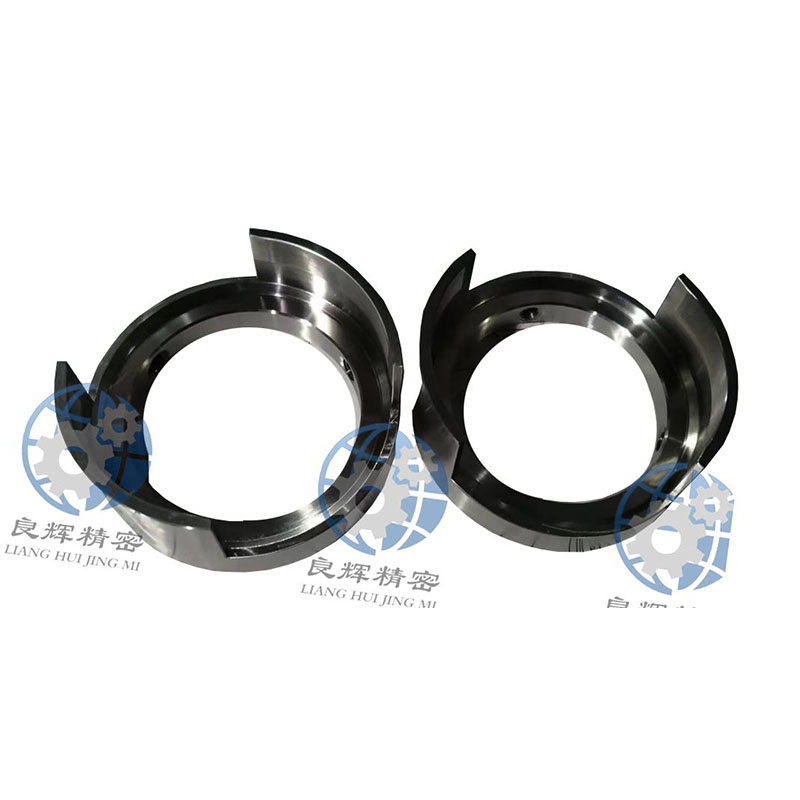

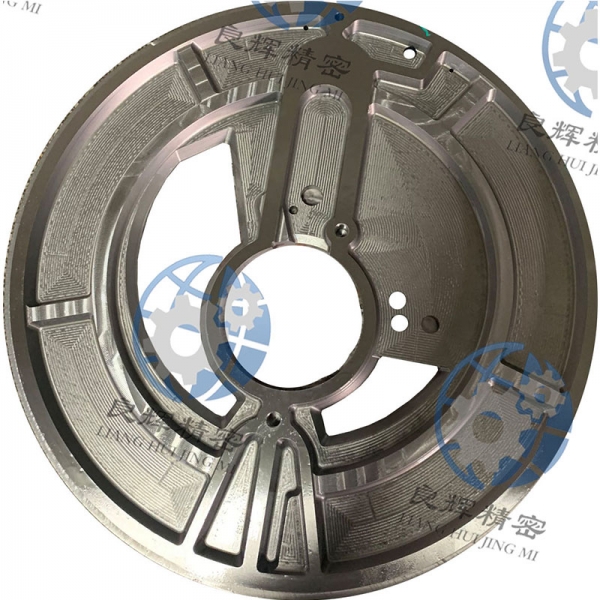

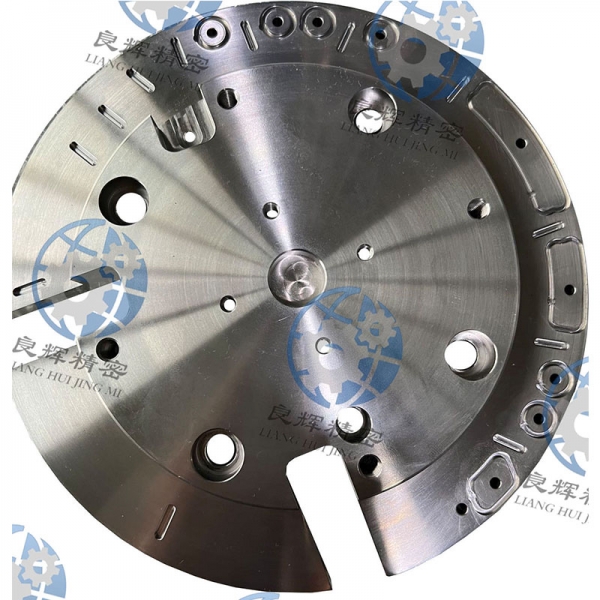

常見的機封零件主要包括密封環、密封座、密封圈、密封套、彈簧等,它們通常由不同材料制成,如橡膠、塑料、金屬等。機封零件的設計和選擇直接影響到設備的密封效果和性能,因此在選擇機封零件時需要考慮介質的性質、溫度、壓力等因素。

Mechanical seal components, commonly known as "mechanical seals", are important parts in mechanical equipment used to prevent liquids or gases from escaping from the rotating shaft core or piston axis of the machine, and to prevent external substances from entering. Machine sealed parts are widely used in various industrial fields, including chemical, petroleum, power, paper, pharmaceutical and other industries. Dalian Precision Parts Processing

The main function of machine sealed parts is to prevent medium leakage and protect the normal operation of equipment, and their performance directly affects the working efficiency and service life of the equipment. Currently, with the continuous development of industrial technology

The types and specifications of machine sealing parts are becoming increasingly diverse to meet the requirements of different working conditions.

Common machine seal components mainly include sealing rings, sealing seats, sealing rings, sealing sleeves, springs, etc. They are usually made of different materials such as rubber, plastic, metal, etc. The design and selection of machine seal parts directly affect the sealing effect and performance of the equipment, so factors such as the properties of the medium, temperature, and pressure need to be considered when selecting machine seal parts.