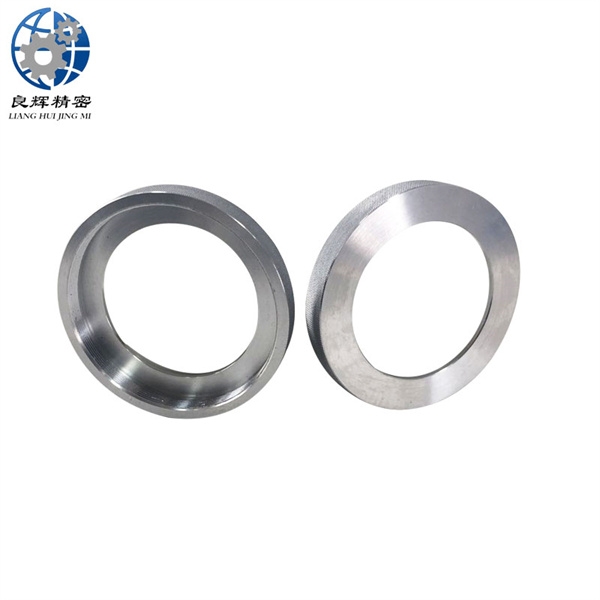

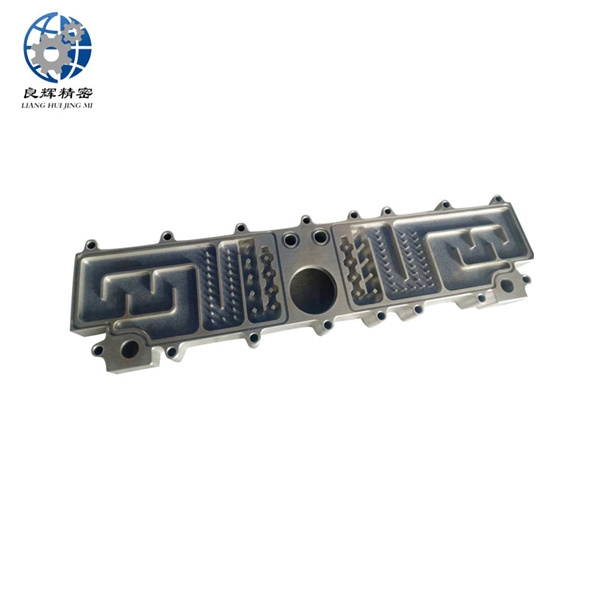

數(shù)控編程是數(shù)控加工準備階段的主要內(nèi)容之一,大連數(shù)控加工通常包括分析零件圖樣 ,確定加工工藝過程;計算走刀軌跡,得出刀位數(shù)據(jù);編寫數(shù)控加工程序;制作控制介質;校對程序及首件試切。

手工編程是指編程的各個階段均由人工完成。利用一般的計算工具,通過各種三角函數(shù)計算方式,人工進行刀具軌跡的運算,并進行指令編制。

這種方式比較簡單,很容易掌握,適應性較大。使用于非模具加工的零件。

Numerical control programming is one of the main contents in the preparation stage of numerical control machining. Dalian numerical control machining usually includes analyzing part drawings and determining the machining process; Calculate the tool path and obtain tool position data; Write CNC machining programs; Create control media; Proofreading program and first piece trial cutting.

Manual programming refers to the process where all stages of programming are completed manually. Using general computing tools and various trigonometric calculation methods, manually calculate the tool path and develop instructions.

This method is relatively simple, easy to master, and adaptable. Used for non mold processed parts.