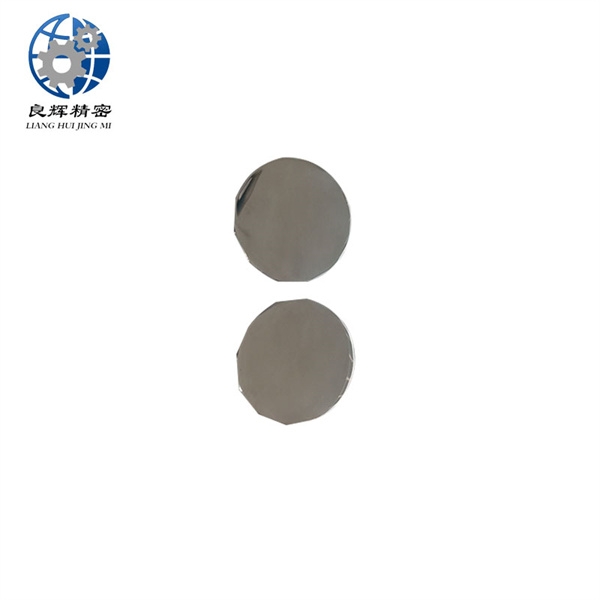

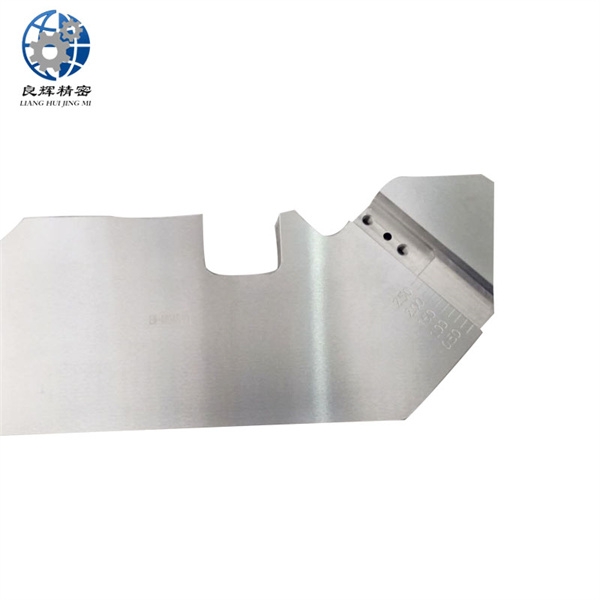

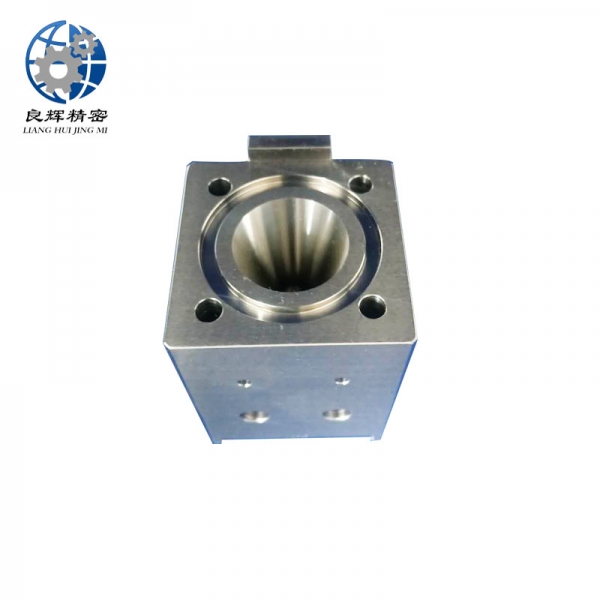

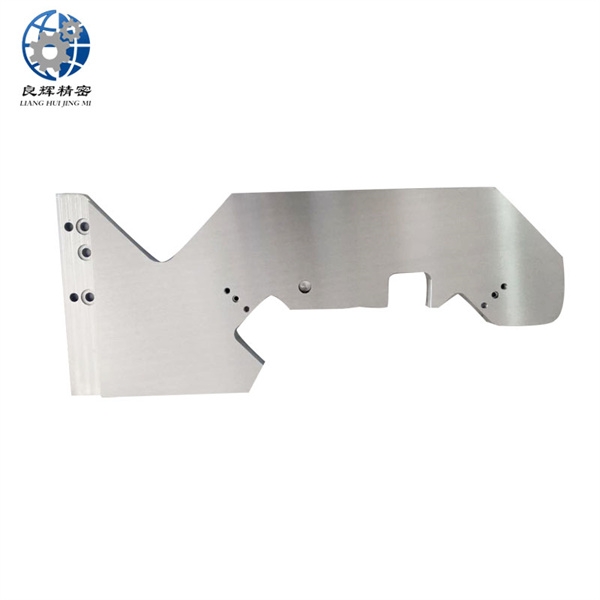

金屬非標準件加工是由客戶提供圖紙,大連數(shù)控加工廠家根據(jù)圖紙利用設備制作出相應的產(chǎn)品,通常是模具居多,公差要求,光潔度都是客戶規(guī)定的,沒有一定的范式。產(chǎn)品從鑄造到精加工完全需要相應的質(zhì)量控制,工序復雜且可變性大,一般成本高于標準件。

The processing of metal non-standard parts is based on drawings provided by customers, and Dalian CNC machining manufacturers use equipment to produce corresponding products according to the drawings. Usually, molds are used, and tolerance requirements and smoothness are specified by customers, without a certain paradigm. The product requires corresponding quality control from casting to precision machining, with complex and variable processes, and generally higher costs than standard parts.