大連機(jī)械加工的零件在加工和裝配過(guò)程中所使用的基準(zhǔn),稱為工藝基準(zhǔn)。工藝基準(zhǔn)按用途不同,又分為定位基準(zhǔn)、測(cè)量基準(zhǔn)和裝配基準(zhǔn)。

1)定位基準(zhǔn):加工時(shí)使工件在機(jī)床或夾具中占據(jù)正確位置所用的基準(zhǔn),稱為定位基準(zhǔn)。按定位元件的不同,較常用的有以下兩類:

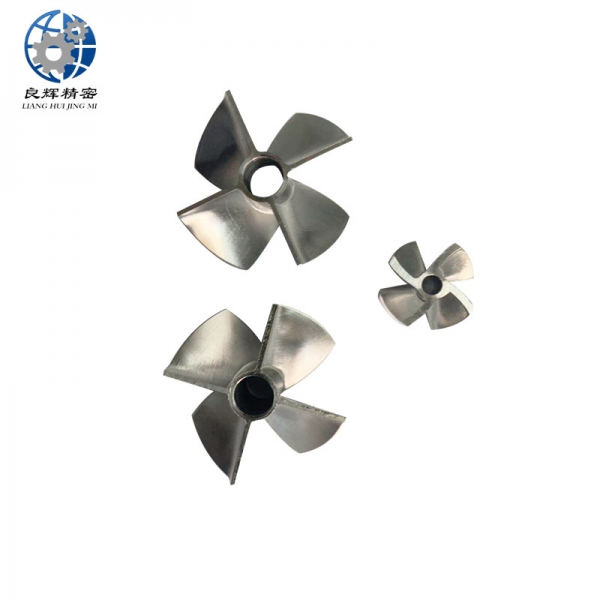

自動(dòng)定心定位:如三爪卡盤定位。

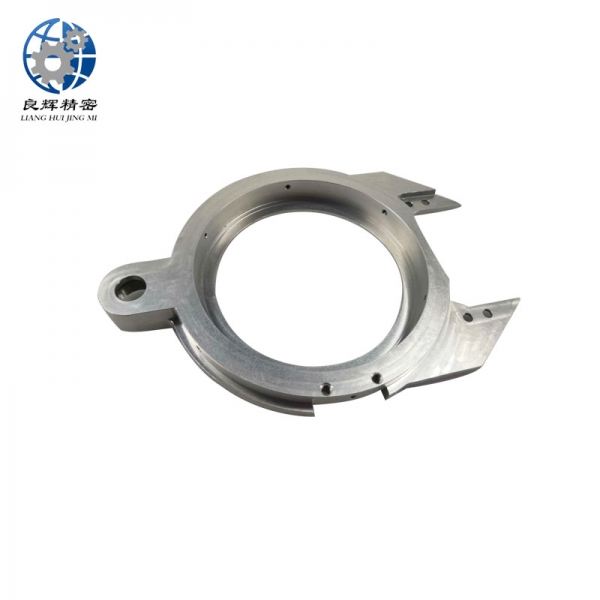

定位套定位:將定位元件做成定位套,如止口盤定位。

其他有在V形架中定位,在半圓孔中定位等。

2)測(cè)量基準(zhǔn):零件檢驗(yàn)時(shí),用以測(cè)量已加工表面尺寸及位置的基準(zhǔn),稱為測(cè)量基準(zhǔn)。

3)裝配基準(zhǔn):裝配時(shí)用以確定零件在部件或產(chǎn)品中位置的基準(zhǔn),稱為裝配基準(zhǔn)。

The reference used in the machining and assembly process of parts processed by Dalian Machinery is called the process reference. Process standards are divided into positioning standards, measurement standards, and assembly standards according to different purposes.

1) Positioning reference: The reference used to ensure that the workpiece occupies the correct position in the machine tool or fixture during processing, known as the positioning reference. According to the different positioning components, there are two commonly used types:

Automatic centering positioning: such as three jaw chuck positioning.

Positioning sleeve positioning: Make the positioning element into a positioning sleeve, such as a stop plate positioning.

Others include positioning in the V-shaped frame, positioning in the semi-circular hole, etc.

2) Measurement benchmark: The benchmark used to measure the size and position of the machined surface during part inspection is called the measurement benchmark.

3) Assembly reference: A reference used during assembly to determine the position of a part in a component or product, known as an assembly reference.