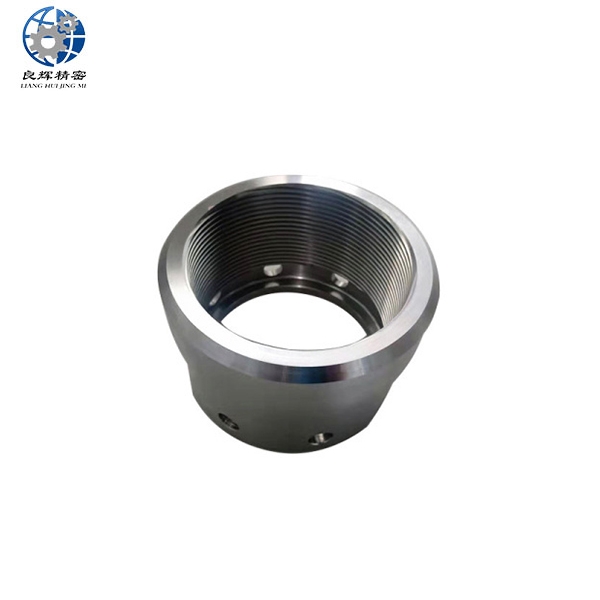

碳化鎢噴涂是將碳化鎢合金以涂層的方式與基材結(jié)合形成碳化鎢耐磨層的大連精密零部件加工,根據(jù)不同工藝可以將碳化鎢噴涂分類(lèi)如下:

1:JP8000碳化鎢噴涂工藝,北京耐默公司以JP8000設(shè)備加出了硬度HV1200硬度的涂層。

2:KN3000碳化鎢噴涂工藝,是以氧乙炔工藝噴涂碳化鎢涂層。

3:真空碳化鎢霧化處理,具有高精度的碳化鎢涂層。

碳化鎢涂層具有硬度高,耐磨性好,熱變形量小的特點(diǎn)。

Tungsten carbide spraying is a precision machining process that combines tungsten carbide alloy with a substrate in the form of a coating to form a tungsten carbide wear-resistant layer. According to different processes, tungsten carbide spraying can be classified as follows:

1: JP8000 tungsten carbide spraying process, Beijing Naimo Company added a coating with a hardness of HV1200 using JP8000 equipment.

2: KN3000 tungsten carbide spraying process uses oxyacetylene process to spray tungsten carbide coating.

3: Vacuum tungsten carbide atomization treatment, with high-precision tungsten carbide coating.

Tungsten carbide coating has the characteristics of high hardness, good wear resistance, and small thermal deformation.