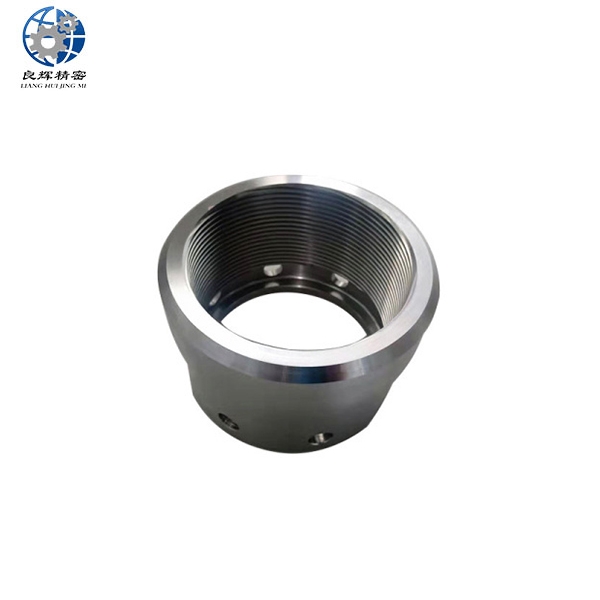

如何銑削螺紋?在大連精密零部件加工螺紋銑床上用盤形銑刀或梳形銑刀進行銑削。盤形銑刀主要用于銑削絲桿、蝸桿等工件上的梯形外螺紋。梳形銑刀用于銑削內(nèi)、外普通螺紋和錐螺紋,由于是用多刃銑刀銑削、其工作部分的長度又大于被加工螺紋的長度,故工件只需要旋轉(zhuǎn)1.25~1.5轉(zhuǎn)就可加工完成,生產(chǎn)率很高。螺紋銑削的螺距精度一般能達 8~9級,表面粗糙度為R5~0.63微米。這種方法適用于成批生產(chǎn)一般精度的螺紋工件或磨削前的粗加工。

How to mill threads? Use disc milling cutters or comb milling cutters to mill threads on precision parts machining milling machines in Dalian. Disc milling cutters are mainly used for milling trapezoidal external threads on workpieces such as screw rods and worm gears. Comb shaped milling cutters are used for milling internal and external ordinary threads and tapered threads. Due to the use of multi edge milling cutters and the length of their working part being greater than the length of the thread being machined, the workpiece only needs to rotate 1.25~1.5 revolutions to complete the machining, resulting in high productivity. The pitch accuracy of thread milling can generally reach 8-9 levels, and the surface roughness is R5~0.63 microns. This method is suitable for mass production of threaded workpieces with general accuracy or rough machining before grinding.