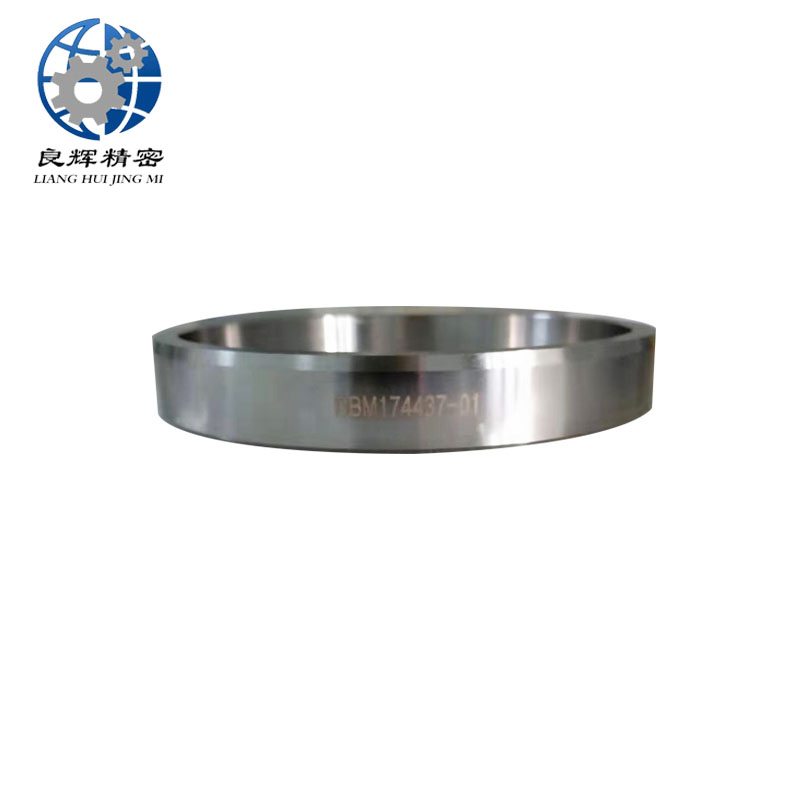

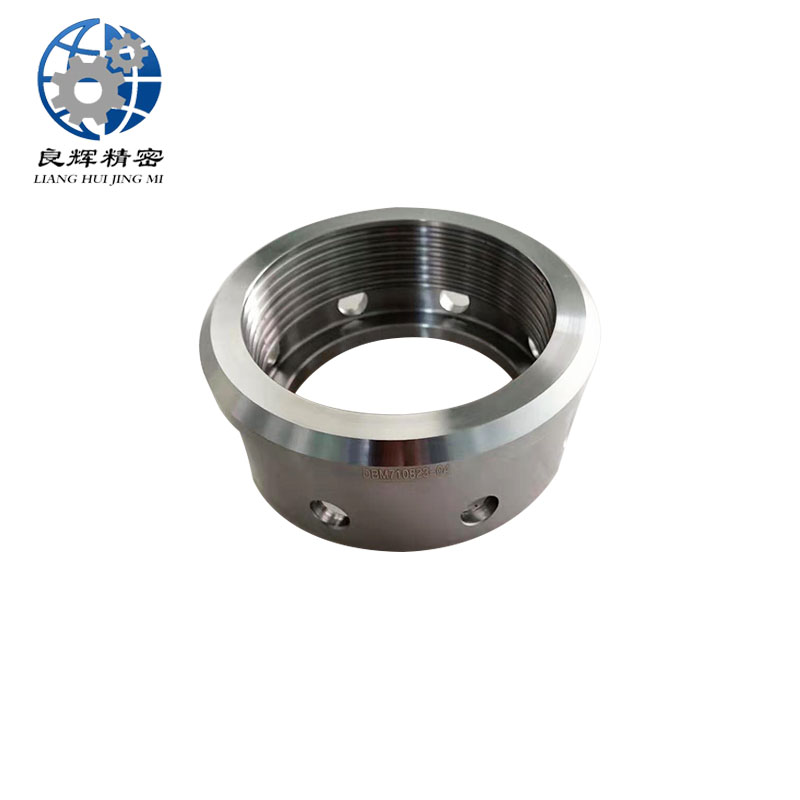

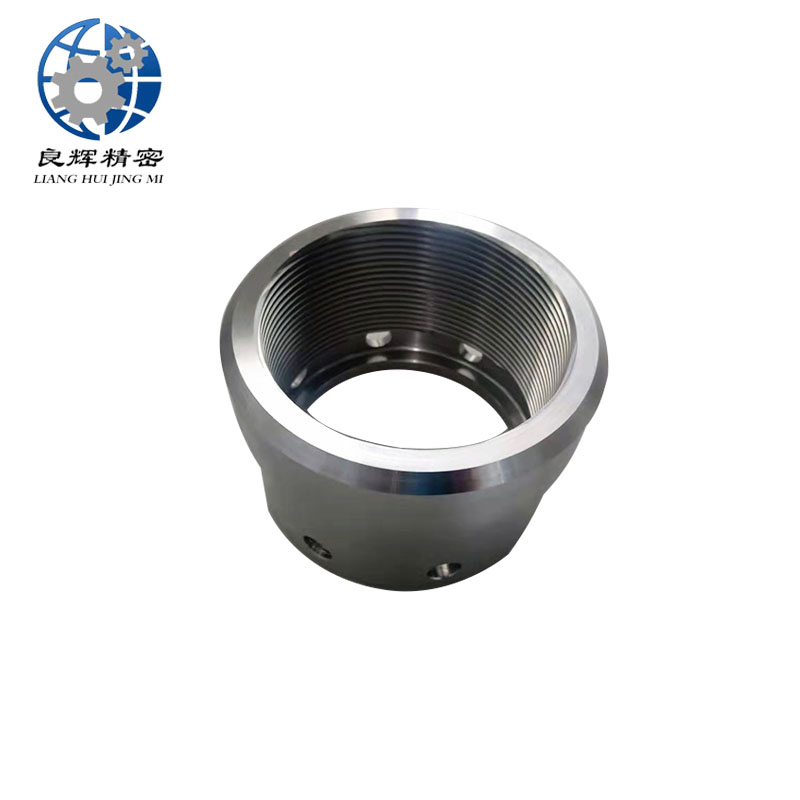

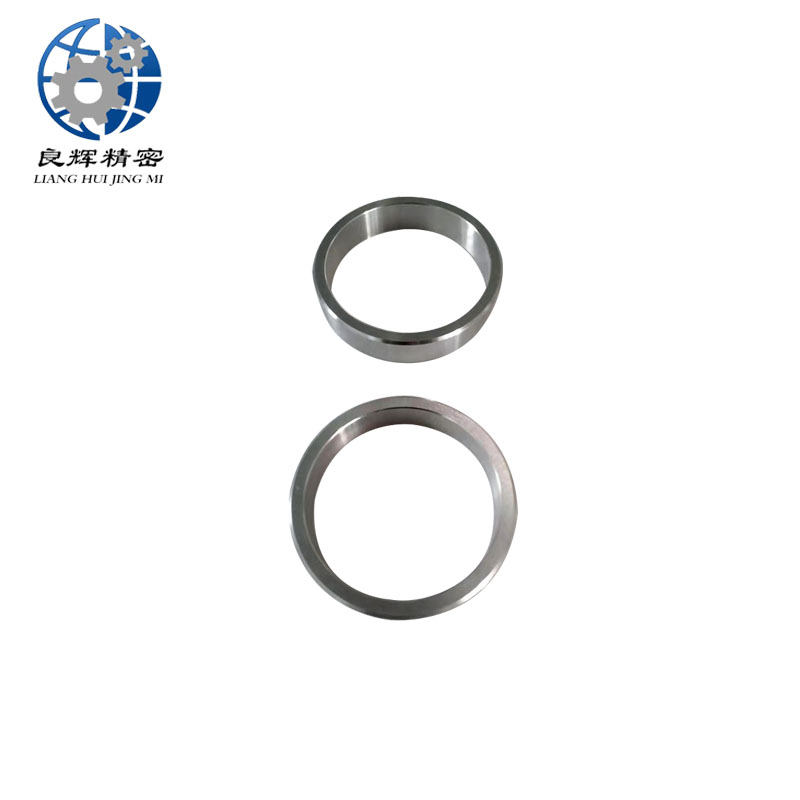

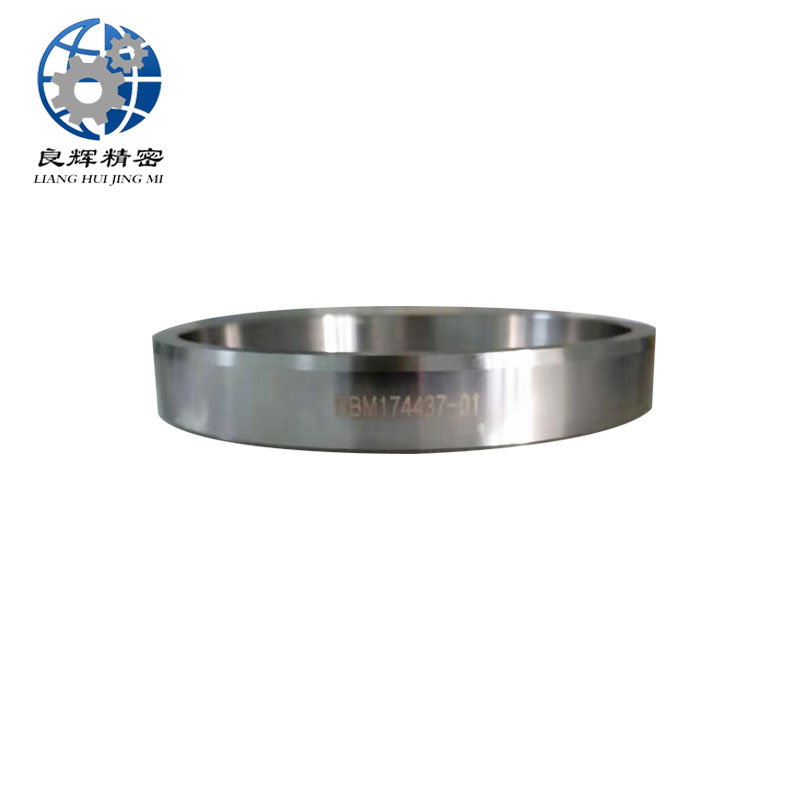

級間襯套,間隔襯套,候部襯套直接的關系,和泵軸軸頸截止閥接觸點及接觸角度:標準規定下瓦背與軸承座接觸面積應在60%以上,軸頸處滑動接觸面上的接觸點密度保持在每平方厘米2一4個點,接觸角度保持在60“一90”。

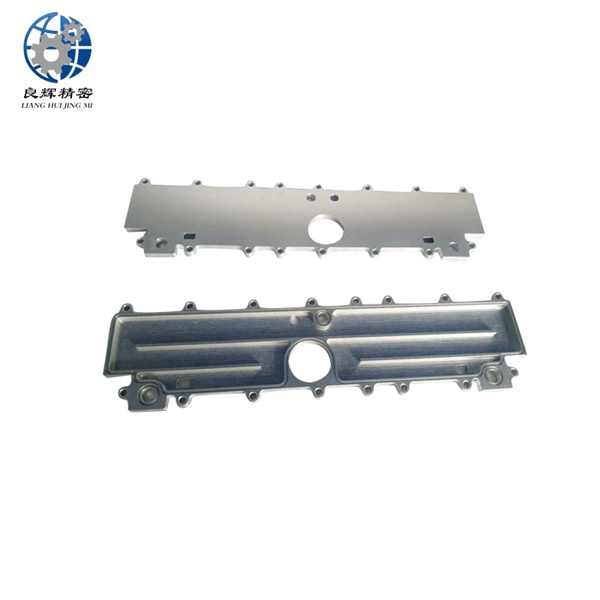

支架和底板。及時發現有振動的支撐件的疲勞情況,防止因為強度和剛度降低造成固有頻率下降。

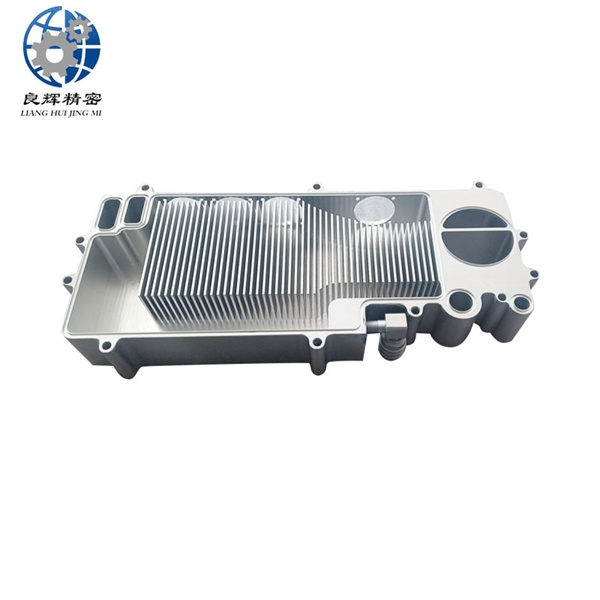

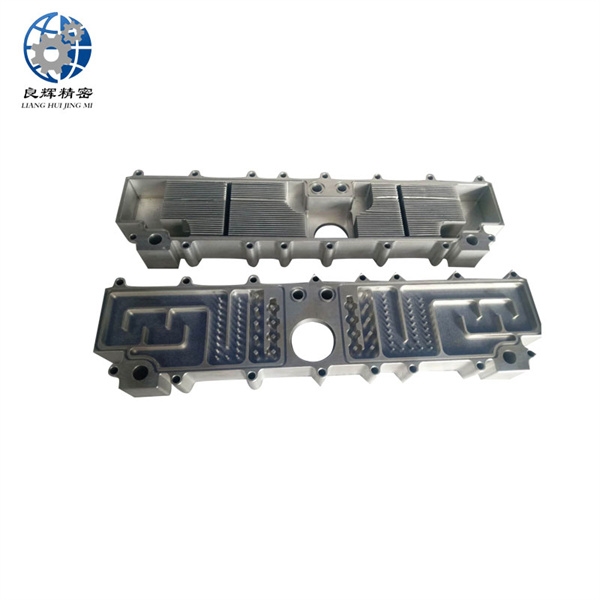

間隙和易損件。級間襯套,間隔襯套,大連良輝機械精密加工候部襯套保證電機軸承間隙合適;適當減壓閥調整葉輪與渦殼之間的間隙;定期檢查、更換葉輪口環、泵體口環、級間襯套、隔板襯套等易磨損零件。

The direct relationship between the inter stage liner, spacing liner, and waiting part liner, as well as the contact point and contact angle with the pump shaft neck globe valve: According to standard regulations, the contact area between the bearing back and the bearing seat should be within 60%

Above, the contact point density on the sliding contact surface at the journal is maintained at 2-4 points per square centimeter, and the contact angle is kept between 60 "and 90". Bracket and base plate. Timely detect the fatigue situation of vibrating support components to prevent a decrease in natural frequency due to a decrease in strength and stiffness.

Gap and vulnerable parts. Inter level bushings, spacing bushings, and precision machined bushings from Dalian Lianghui Machinery ensure appropriate clearance between motor bearings; Adjust the gap between the impeller and the volute appropriately with a pressure reducing valve; Regularly inspect and replace wear-resistant parts such as impeller mouth rings, pump body mouth rings, inter stage bushings, and baffle bushings.