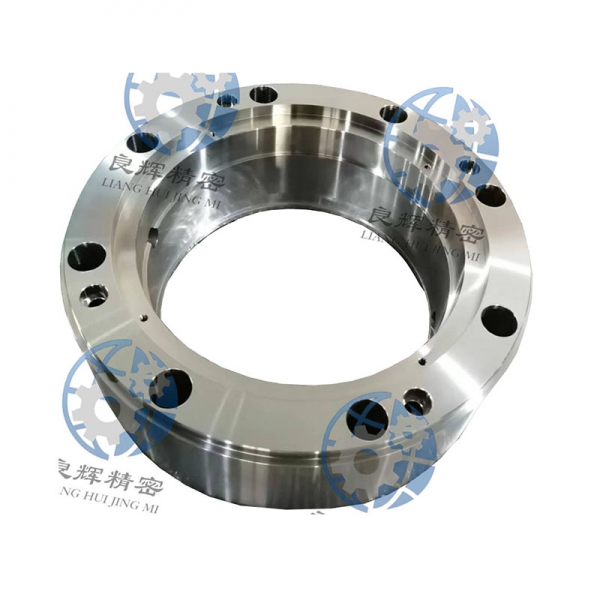

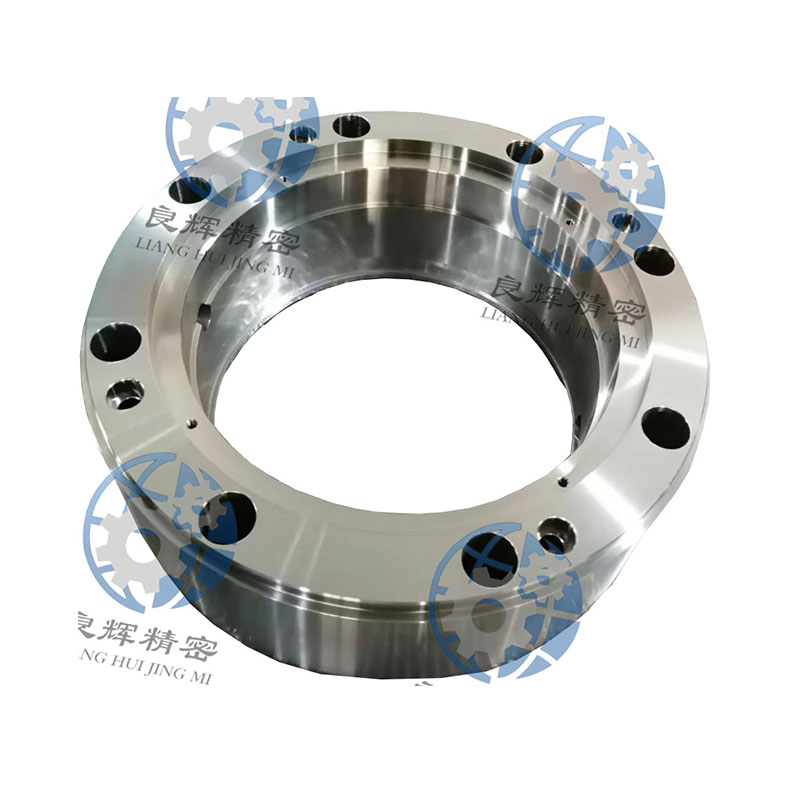

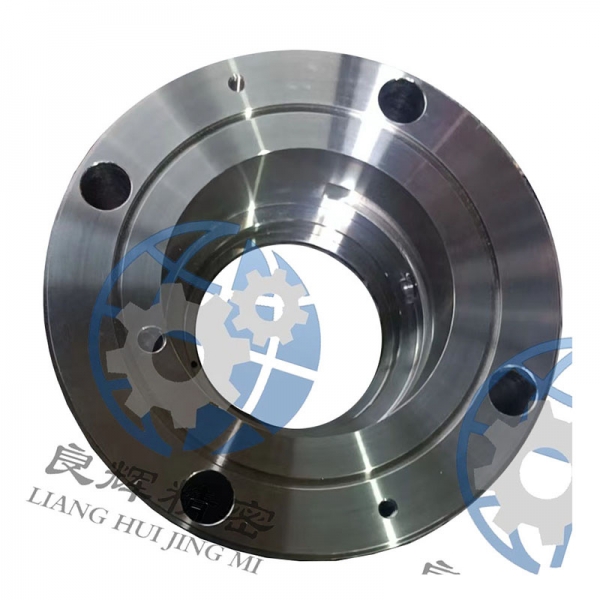

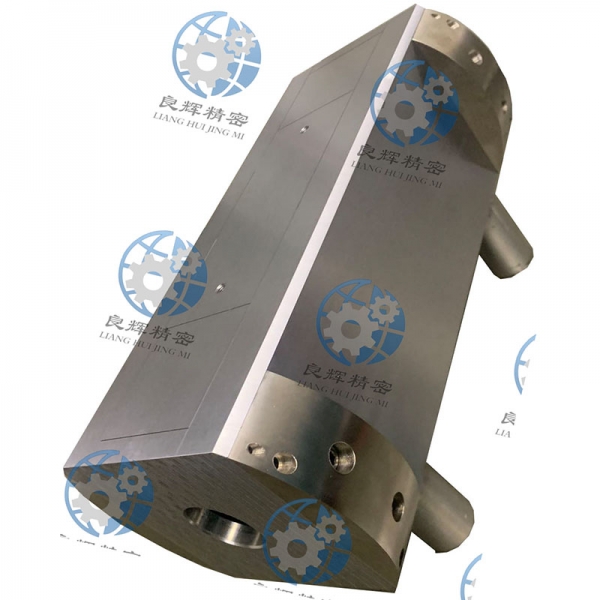

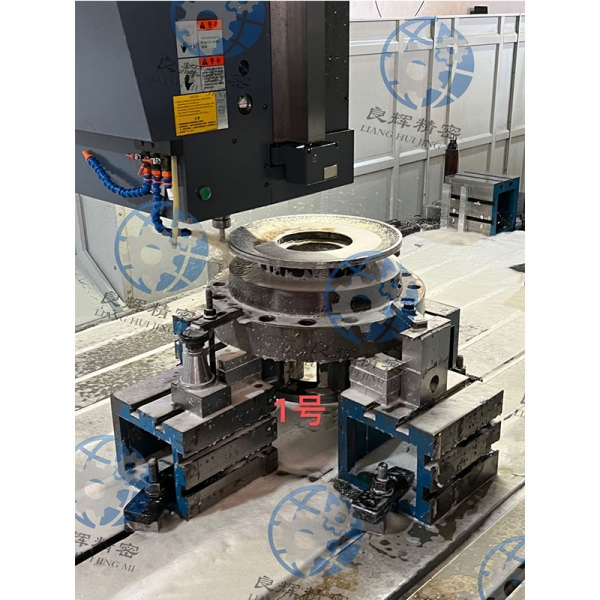

機封零件是一種用于密封機器或設備的零件,通常用于防止液體或氣體泄漏。機封零件的主要作用是保持機器內部的密封性,防止外部的雜質進入,確保機器的正常運轉。大連精密零部件加工

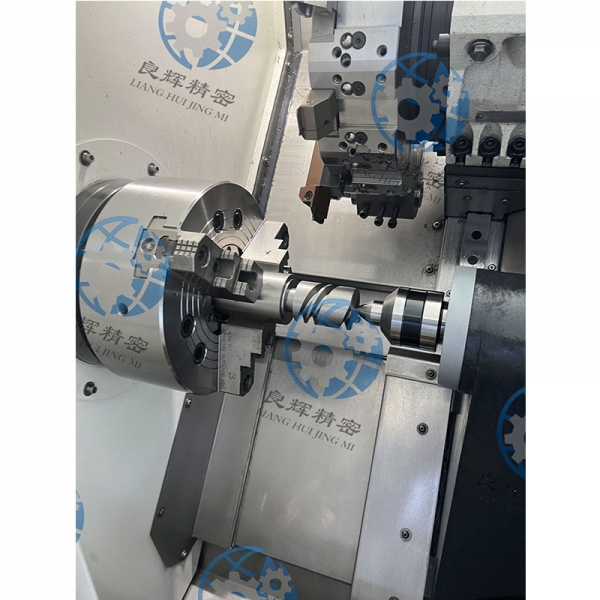

機封零件主要分為靜態密封和動態密封兩種類型。靜態密封用于不需要移動的部件之間,如連接管道、閥門等地方;而動態密封則用于需要移動的部件之間,如活塞、軸承等地方。

機封零件的材料通常由橡膠、金屬、塑料等材料制成,根據不同的使用環境和要求選擇不同的材料。橡膠密封件具有較好的密封性能和耐磨損性能,適用于一些特殊的工作環境;金屬密封件具有良好的耐高溫、耐腐蝕性能,適用于高溫高壓的工作環境;塑料密封件則具有較好的耐磨損性能和耐化學腐蝕性能,適用于一些特殊的工作環境。

Machine seal parts are a type of component used to seal machines or equipment, typically used to prevent liquid or gas leakage. The main function of machine sealing parts is to maintain the sealing inside the machine, prevent external impurities from entering, and ensure the normal operation of the machine. Dalian Precision Parts Processing

Machine sealed components are mainly divided into two types: static seals and dynamic seals. Static sealing is used between components that do not require movement, such as connecting pipes, valves, etc; And dynamic sealing is used between parts that need to be moved, such as pistons, bearings, etc.

The material of machine seal parts is usually made of rubber, metal, plastic and other materials, and different materials are selected according to different usage environments and requirements. Rubber seals have good sealing performance and wear resistance, and are suitable for some special working environments; Metal seals have good resistance to high temperatures and corrosion, and are suitable for working environments with high temperatures and pressures; Plastic seals have good wear resistance and chemical corrosion resistance, and are suitable for some special working environments.