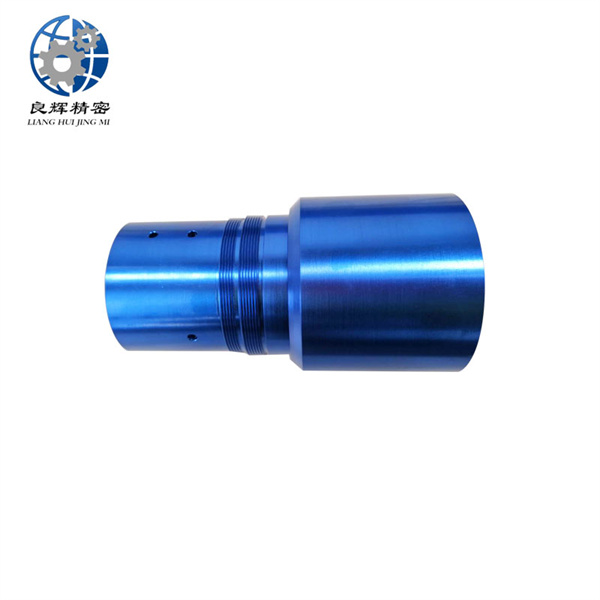

鋁質材料在空氣中是極不穩定的,容易生成用肉眼也難以識別的氧化膜。由于大連數控加工鋁件加工工藝方法的不同,如鑄造成型,或是由延壓板材直接剪切而成,或是機械精細加工成型,或是經不同工藝成型后又經熱處理或焊接等,工件表面都會呈現不同狀態,不同程度的污物或痕跡,為此在前處理工序中必須根據工件表面的實際情況選擇前處理的工藝方法。

Aluminum materials are extremely unstable in air and are prone to forming oxide films that are difficult to identify with the naked eye. Due to the different processing methods of aluminum parts in Dalian CNC machining, such as casting molding, direct cutting from extruded sheet metal, mechanical fine processing molding, or forming through different processes and then heat treatment or welding, the surface of the workpiece will present different states and degrees of dirt or marks. Therefore, in the pre-treatment process, the pre-treatment method must be selected according to the actual situation of the workpiece surface.