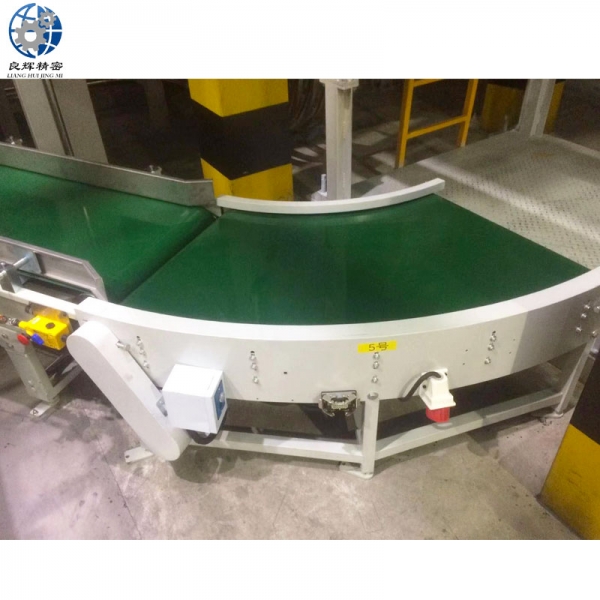

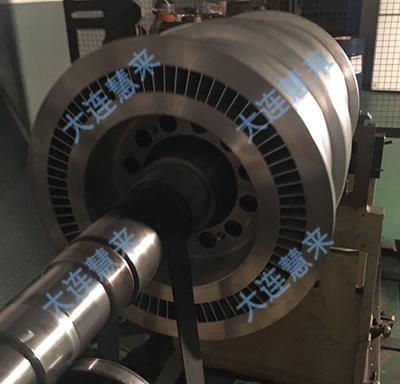

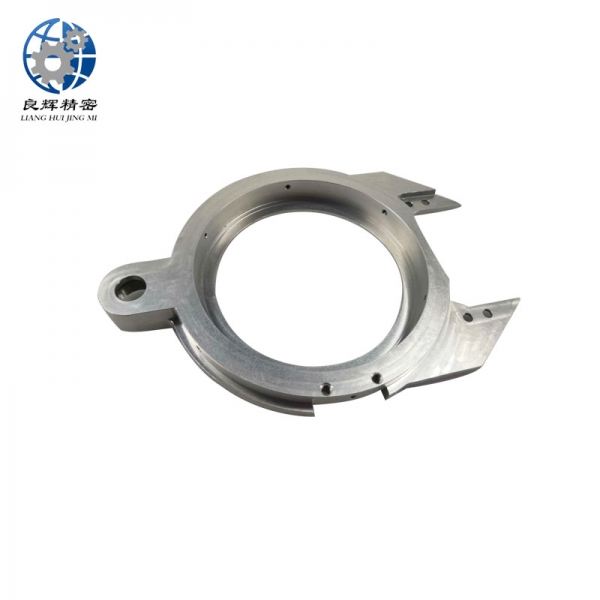

在大連機械加工生產(chǎn)過程中,凡是改變生產(chǎn)對象的形狀、尺寸、位置和性質(zhì)等,使其成為成品或者半成品的過程稱為工藝過程。它是生產(chǎn)過程的主要部分。工藝過程又可分為鑄造、鍛造、沖壓、焊接、機械加工、裝配等工藝過程,機械制造工藝過程一般是指零件的機械加工工藝過程和機器的裝配工藝過程的總和,其他過程則稱為輔助過程,例如運輸、保管、動力供應、設備維修等。工藝過程又是由一個或若干個順序排列的工序組成的,一個工序由有若干個工步組成。

In the process of mechanical processing and production in Dalian, the process of changing the shape, size, position, and properties of the production object to make it a finished or semi-finished product is called a process. It is a major part of the production process. The manufacturing process can be divided into casting, forging, stamping, welding, mechanical processing, assembly and other processes. The mechanical manufacturing process generally refers to the sum of the mechanical processing process of parts and the assembly process of machines. Other processes are called auxiliary processes, such as transportation, storage, power supply, equipment maintenance, etc. The manufacturing process is composed of one or several sequentially arranged processes, with each process consisting of several steps.