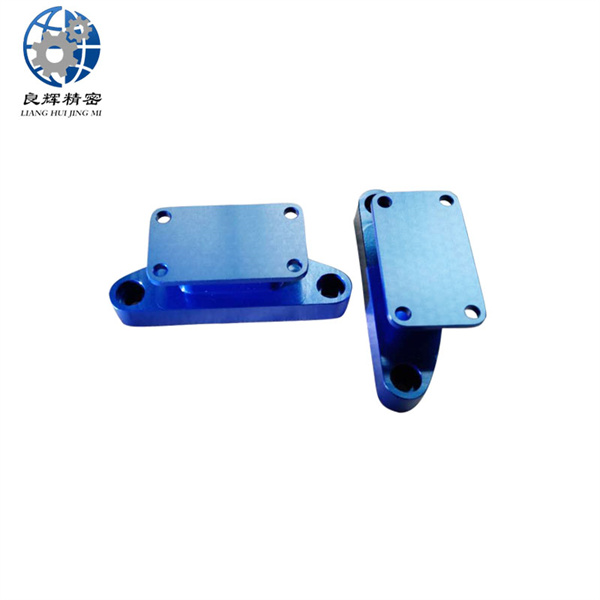

精密大連機械加工的工藝效果是:

①零件的幾何形狀和相互位置精度達到微米或角秒級;

②零件的界限或特征尺寸公差在微米以下;

③零件表面微觀不平度(表面不平度平均高度差)小于0.1 微米;

④互配件能滿足配合力的要求;

⑤部分零件還能滿足精確的力學或其他物理特性要求,如浮子陀螺儀扭桿的扭轉剛度、撓性元件的剛度系數等。

The process effect of precision machining in Dalian is:

① The geometric shape and mutual position accuracy of the parts reach the micrometer or arcsecond level;

② The boundary or characteristic dimension tolerance of the parts is below micrometers;

③ The micro roughness of the part surface (average height difference of surface roughness) is less than 0.1 micrometers;

④ Mutual accessories can meet the requirements of mating force;

⑤ Some parts can also meet precise mechanical or other physical property requirements, such as the torsional stiffness of the float gyroscope torsion bar and the stiffness coefficient of the flexible element.